Print: 02 Nov 2025

RAMPAL POWER PLANT

A distinct model among coal-based plants

According to engineers who have inspected Rampal alongside other coal-fired plants, Rampal’s FGD technology is fully integrated with the boiler and cannot be bypassed

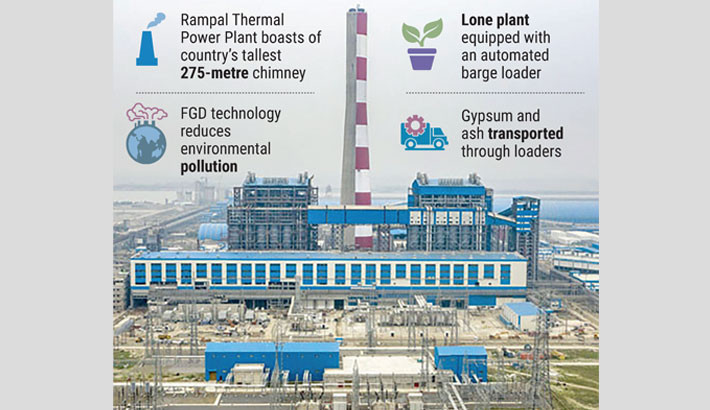

While coal-based power plants remain a major contributor to Bangladesh's national grid, the Rampal Thermal Power Plant in Bagerhat is emerging as a distinct model in both design and technology. The 1,320-MW facility- jointly operated by Bangladesh and India- features several innovations that set it apart from the country's other coal-fired plants.

An integrated Flue Gas Desulfurisation (FGD) system with no bypass option makes Rampal unique, ensuring effective prevention of sulfur oxide emissions.

The plant also employs low-NOx emission technology, reducing nitrogen oxide levels. Through the FGD process, sulfur oxides are converted into gypsum, which, along with coal ash, is transported using an automated barge loader imported from the Netherlands. These byproducts are sold to cement factories through open tenders, preventing environmental pollution. In contrast, most other plants transport gypsum and ash in open trucks, causing environmental damage.

According to engineers who have inspected Rampal alongside other coal-fired plants, Rampal’s FGD technology is fully integrated with the boiler and cannot be bypassed. At other plants, operations can continue through a bypass if the FGD system fails. But at Rampal, any attempt to bypass would require shutting down the boiler entirely, halting power generation. This makes Rampal fundamentally different from its counterparts.

Another distinction lies in byproduct management. At Rampal, ash and gypsum are loaded directly from the jetty onto barges for delivery to cement factories, while in most other plants, these materials are transported in open trucks, causing pollution.

The plant also features the tallest chimney in Bangladesh, rising 275 metres- far higher than the 220-metre chimney at the Payra Thermal Power Plant in Patuakhali. It is considered the tallest man-made structure in the country. The chimney’s height allows carbon emissions to disperse more gradually into the atmosphere, reducing environmental impact.

Rampal Project Director Ramanath Pujari said coal used at the plant is imported from Indonesia and undergoes quality testing both before shipment and after unloading. “We never compromise on coal quality,” he said. Pujari noted that while there were procurement challenges earlier this year, there was no coal shortage during Ramadan thanks to the Bangladesh Power Development Board. “We are now receiving coal regularly. If the weather remains favourable, Rampal will even maintain stocks beyond its requirements,” he added.

Asked how Rampal differs from other plants, the project director said:

“This is a unique coal-based power plant, built with a distinctive design and advanced features. From my long experience working in Indian power plants, I can say this 1,320 MW supercritical plant has been built in full compliance with environmental standards. It uses supercritical technology, currently the most effective method for coal-based power generation. The FGD system prevents sulfur emissions, the low-NOx boiler cuts nitrogen oxides, and it is a zero-discharge plant. Unlike others, we have no bypass system. We monitor environmental impacts daily and ensure carbon emissions remain within limits. Sulfur dioxide levels here are also very low.”

The reporter can be reached at: [email protected]

More From Bangladesh

More From Bangladesh

RAMPAL POWER PLANT

A distinct model among coal-based plants

According to engineers who have inspected Rampal alongside other coal-fired plants, Rampal’s FGD technology is fully integrated with the boiler and cannot be bypassed

While coal-based power plants remain a major contributor to Bangladesh's national grid, the Rampal Thermal Power Plant in Bagerhat is emerging as a distinct model in both design and technology. The 1,320-MW facility- jointly operated by Bangladesh and India- features several innovations that set it apart from the country's other coal-fired plants.

An integrated Flue Gas Desulfurisation (FGD) system with no bypass option makes Rampal unique, ensuring effective prevention of sulfur oxide emissions.

The plant also employs low-NOx emission technology, reducing nitrogen oxide levels. Through the FGD process, sulfur oxides are converted into gypsum, which, along with coal ash, is transported using an automated barge loader imported from the Netherlands. These byproducts are sold to cement factories through open tenders, preventing environmental pollution. In contrast, most other plants transport gypsum and ash in open trucks, causing environmental damage.

According to engineers who have inspected Rampal alongside other coal-fired plants, Rampal’s FGD technology is fully integrated with the boiler and cannot be bypassed. At other plants, operations can continue through a bypass if the FGD system fails. But at Rampal, any attempt to bypass would require shutting down the boiler entirely, halting power generation. This makes Rampal fundamentally different from its counterparts.

Another distinction lies in byproduct management. At Rampal, ash and gypsum are loaded directly from the jetty onto barges for delivery to cement factories, while in most other plants, these materials are transported in open trucks, causing pollution.

The plant also features the tallest chimney in Bangladesh, rising 275 metres- far higher than the 220-metre chimney at the Payra Thermal Power Plant in Patuakhali. It is considered the tallest man-made structure in the country. The chimney’s height allows carbon emissions to disperse more gradually into the atmosphere, reducing environmental impact.

Rampal Project Director Ramanath Pujari said coal used at the plant is imported from Indonesia and undergoes quality testing both before shipment and after unloading. “We never compromise on coal quality,” he said. Pujari noted that while there were procurement challenges earlier this year, there was no coal shortage during Ramadan thanks to the Bangladesh Power Development Board. “We are now receiving coal regularly. If the weather remains favourable, Rampal will even maintain stocks beyond its requirements,” he added.

Asked how Rampal differs from other plants, the project director said:

“This is a unique coal-based power plant, built with a distinctive design and advanced features. From my long experience working in Indian power plants, I can say this 1,320 MW supercritical plant has been built in full compliance with environmental standards. It uses supercritical technology, currently the most effective method for coal-based power generation. The FGD system prevents sulfur emissions, the low-NOx boiler cuts nitrogen oxides, and it is a zero-discharge plant. Unlike others, we have no bypass system. We monitor environmental impacts daily and ensure carbon emissions remain within limits. Sulfur dioxide levels here are also very low.”

The reporter can be reached at: [email protected]